Zn-rich BOF sludge

In the EU ArcelorMittal (AM) generates 350 kt/y fine, Zn-rich Basic Oxygen Furnace (BOF) steelmaking sludge, which requires storage or landfilling.

In 2017-18 AM developed, in collaboration with KU Leuven, a process that selectively extracts Zn, leaving behind an Fe-rich residue that is internally recycled. This process was recently published [reference: Nerea Rodriguez Rodriguez et al., Selective Removal of Zinc from BOF Sludge by Leaching with Mixtures of Ammonia and Ammonium Carbonate, Journal of Sustainable Metallurgy, 2020. [Download Open Access paper here]].

In SAMEX, AM, Tecnalia (TEC) & KU Leuven (KUL) will upscale this process from TRL5 to TRL7. To do so, TEC, AM and KUL aim to check at pilot plant level the capability to treat AM’s Zn-rich, fine BOF sludge, generating a cleaned Fe-rich residue that can be internally recycled in the sinter plant (and fed to the BF) and a ZnS precipitate product that can be sold to the zinc industry, thereby providing a nucleus for industrial symbiosis.

SAMEX flowsheet

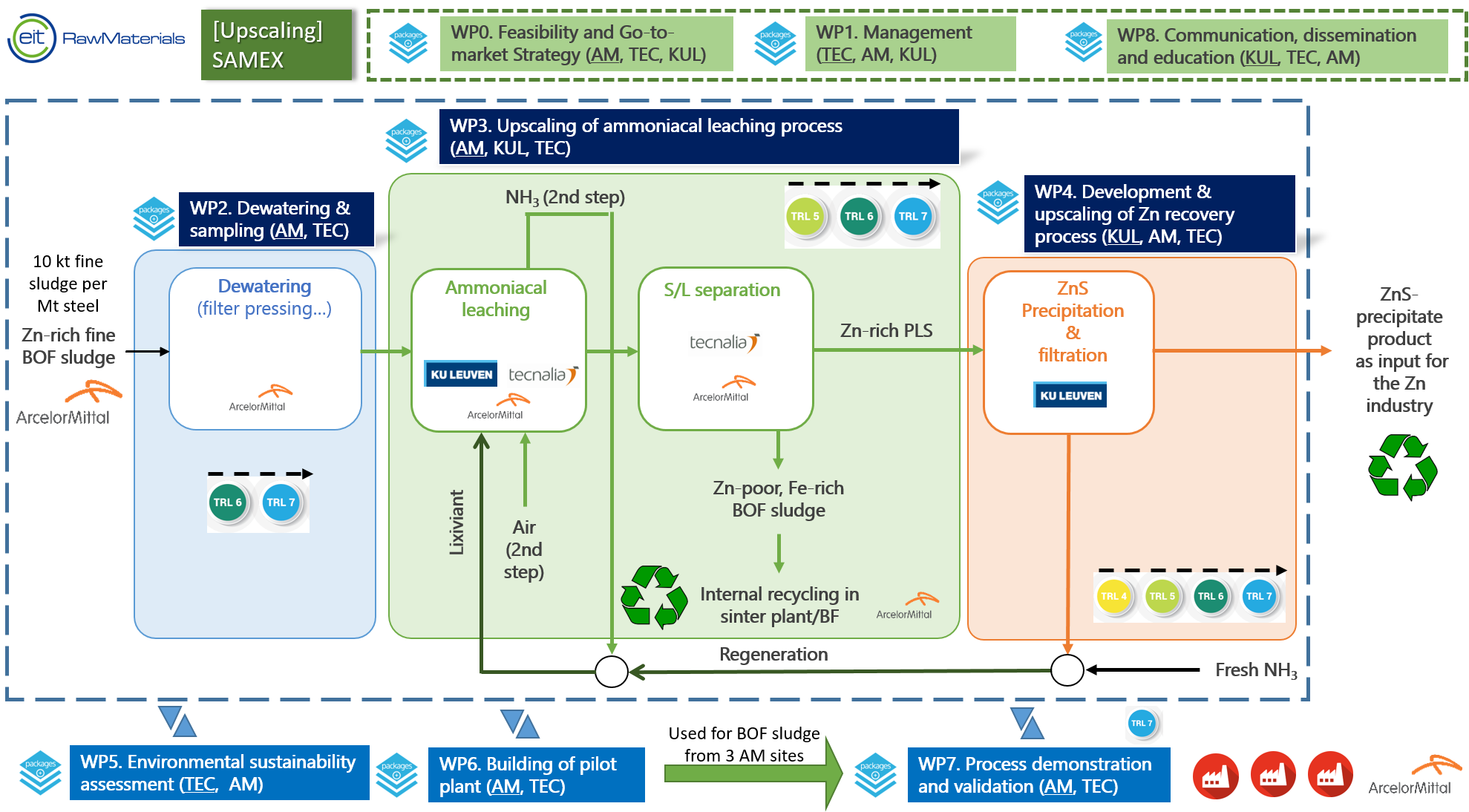

The SAMEX flowsheet (Figure 1) and the to be built pilot plant will consist of several units: (a) dewatering unit, (b) leaching reactor incl. air injection and NH3 regeneration, (c) solid/liquid (filter press) separation, (d) ZnS precipitation.

The pilot plant will be used to test fine BOF sludges from different AM plants in Europe. As such, the SAMEX flowsheet is demonstrated and validated, allowing the replication of the flowsheet to a larger set of AM plants in Europe, who are thus the users of the SAMEX end results and provide the required market uptake. If successful and economically cost-effective, AM would implement the process in at least 1/3 of its EU-plants within three years after the end of the project.

The SAMEX flowsheet can also benefit other sludge producers in EU who face similar issues. The Go-To-Market WP is driven by AM and is supported by dedicated WPs/tasks targeting the LCA and the evaluation of the process economics of the SAMEX flowsheet, as it needs to be confirmed that the SAMEX flowsheet is efficient, cost effective and eco-friendly.

All these key elements of the project are schematically shown in Figure 1, which combines the SAMEX flowsheet with the SAMEX project Pert chart.

Figure 1: Samex flowsheet and project Pert Chart (initial and targeted TRL levels are indicated for all technical WPs).