SULTAN, the European Training Network for the remediation and reprocessing of sulphidic mining waste sites, has launched its long-awaited Thematic Section in the Journal of Sustainable Metallurgy. The Thematic Section comprises 10 research papers on the different aspects of the SULTAN (near-) zero-waste reprocessing value chain for Europe’s sulphidic extractive waste. Two case studies are highlighted: i.e. Plombières, a small-scale historical tailing site in Belgium, and Neves Corvo, the large-scale Tailings Storage Facility of the active Neves Corvo mine in Portugal. The Thematic Section, including a preface describing the bottlenecks and opportunities of sulphidic tailings remining, is now available at Springer.

Towards a Combined Remediation and Resource Recovery Approach

As a result of the SULTAN project, a Thematic Section within the Journal of Sustainable Metallurgy has now been published, comprising 10 research papers on the different aspects of the SULTAN (near-) zero-waste reprocessing value chain for Europe’s extractive waste. The full section is now available at the Springer website.

The preface of the thematic section, summarising the main bottlenecks and opportunities encountered in the (re)mining of sulphidic mining waste, can be read here: Preface to the Thematic Section: Mine Tailings: Problem or Opportunity? Towards a Combined Remediation and Resource Recovery Approach (Machiels, L., Frenzel, M., Goldmann, D. et al. Preface to the Thematic Section: Mine Tailings: Problem or Opportunity? Towards a Combined Remediation and Resource Recovery Approach. J. Sustain. Metall. 7, 1440–1443 (2021). https://doi.org/10.1007/s40831-021-00468-7)

To evaluate the SULTAN near-zero-waste-processing scheme, three case studies have been analysed, being (1) the historical Zn-Pb mining and metallurgical processing area in Plombières, Belgium; (2) the active Cu-Zn Neves Corvo mine in Portugal; and (3) the historical Cu-Zn-Pb tailings in the Freiberg district, Germany.

As the case studies strongly vary, with respect to both technical aspects (valuable/hazardous metal types and content, mineralogy, grain size, etc.) as non-technical aspects (size, ownership, land protection status, legislation for re-mining), a site-specific approach is needed to evaluate the re-mining potential. While in the thematic section results of the Plombières and Neves Corvo case studies are presented, results from the Freiberg case study will be published separately in future contributions.

The Plombières Case—An Example of a Small-Scale Historical Tailing site

Three papers in the thematic section study different aspects of the assessment of the re-mining potential of the Plombières historical mining site in Belgium. As this example of a small scale historical mining site clearly lacks the economies of scale required to be mined from an economic perspective, a decision to actually re-mine such smaller sites is likely only possible if the site poses acute environmental and/or health risks.

While present-day tailings are in general well protected in state-of-the-art tailing storage facilities, historical tailings typically lack the required safety and environmental protection measures. If these risks require the removal of the tailings to state-of-the-art tailing storage facilities or landfills, a re-mining approach could still be considered as an alternative. Resource recovery can then partially compensate for the remediation costs.

The papers on the Plombières case study can be viewed here:

- Chemical Leaching of Sulfidic Mining Waste, Plombières Tailings Pond, Eastern Belgium: Insights from a Mineralogical Approach – Bevandić, S., Xanthopoulos, P. & Muchez, P. Chemical Leaching of Sulfidic Mining Waste, Plombières Tailings Pond, Eastern Belgium: Insights from a Mineralogical Approach. J. Sustain. Metall. 7, 1444–1455 (2021). https://doi.org/10.1007/s40831-021-00445-0

- Characterization of Mine Waste from a Former Pb–Zn Mining Site: Reactivity of Minerals During Sequential Extractions – Cappuyns, V., Campen, V., Bevandić, S. et al. Characterization of Mine Waste from a Former Pb–Zn Mining Site: Reactivity of Minerals During Sequential Extractions. J. Sustain. Metall. 7, 1456–1468 (2021). https://doi.org/10.1007/s40831-021-00455-y

- Turning Mine Waste into a Ceramic Resource: Plombières Tailing Case – Simão, F.V., Chambart, H., Vandemeulebroeke, L. et al. Turning Mine Waste into a Ceramic Resource: Plombières Tailing Case. J. Sustain. Metall. 7, 1469–1482 (2021). https://doi.org/10.1007/s40831-021-00442-3

The Neves Corvo Case—An Example of a Large-Scale Present-Day Tailings storage facility.

Seven papers of the thematic section are dedicated to different aspects of the characterization, metal extraction, and valorisation of the mineral fraction of the Neves Corvo extractive waste. Compared to the Plombières case, the reprocessing of the Neves Corvo tailings seems to be more realistic.

The sheer volume of the Neves Corvo tailings facilitates the reprocessing at large scale, triggering favourable economies of scale. Furthermore, heterogeneity is expected to be much smaller. Concurrently, from a legislative and Social License to Operate perspective, this case is more straightforward as it is already categorized as a site of mining activity, in contrast with the Plombières tailings that are located in a natural reserve.

If the process economics for the recovery of copper and zinc are not satisfactory, other aspects could contribute to a positive business case, such as the recovery of sulfur for sulfuric acid production, or the use of the mineral fraction after metal recovery in construction applications. In this way, a near-zero-waste treatment scheme could be developed, which would also mean that the tailing storage facility can be strongly reduced in size, while mitigating long-term risks such as AMD.

The papers on the Neves Corvo case study can be viewed here:

- Physical–Chemical Characterization of the Neves Corvo Extractive Mine Residues: A Perspective Towards Future Mining and Reprocessing of Sulfidic Tailings – Escobar, A.G., Relvas, J.M.R.S., Pinto, Á.M.M. et al. Physical–Chemical Characterization of the Neves Corvo Extractive Mine Residues: A Perspective Towards Future Mining and Reprocessing of Sulfidic Tailings. J. Sustain. Metall. 7, 1483–1505 (2021). https://doi.org/10.1007/s40831-021-00428-1

- Silylated Thiol-Containing Cellulose Nanofibers as a Bio-Based Flocculation Agent for Ultrafine Mineral Particles of Chalcopyrite and Pyrite – Coelho Braga de Carvalho, A.L., Ludovici, F., Goldmann, D. et al. Silylated Thiol-Containing Cellulose Nanofibers as a Bio-Based Flocculation Agent for Ultrafine Mineral Particles of Chalcopyrite and Pyrite. J. Sustain. Metall. 7, 1506–1522 (2021). https://doi.org/10.1007/s40831-021-00439-y

- Leaching of Cu, Zn, and Pb from Sulfidic Tailings Under the Use of Sulfuric Acid and Chloride Solutions – Schueler, T.A., de Aguiar, P.F., Vera, Y.M. et al. Leaching of Cu, Zn, and Pb from Sulfidic Tailings Under the Use of Sulfuric Acid and Chloride Solutions. J. Sustain. Metall. 7, 1523–1536 (2021). https://doi.org/10.1007/s40831-021-00446-z

- Fundamental Insights in Alcoholic Ammoniacal Systems for Selective Solvometallurgical Extraction of Cu, Zn, and Pb from Tailings – Everaert, M., Guerrero, F., Kamariah, N. et al. Fundamental Insights in Alcoholic Ammoniacal Systems for Selective Solvometallurgical Extraction of Cu, Zn, and Pb from Tailings. J. Sustain. Metall. 7, 1537–1551 (2021). https://doi.org/10.1007/s40831-021-00382-y

- Recovery of Copper from Ammoniacal Leachates by Ion Flotation – Xanthopoulos, P., Kalebić, D., Kamariah, N. et al. Recovery of Copper from Ammoniacal Leachates by Ion Flotation. J. Sustain. Metall. 7, 1552–1564 (2021). https://doi.org/10.1007/s40831-021-00363-1

- Closing the Loop in Ion Flotation: Recovery of Copper, Regeneration and Reuse of Collector from the Foam Phase by a Solvometallurgical Process – Xanthopoulos, P., Binnemans, K. Closing the Loop in Ion Flotation: Recovery of Copper, Regeneration and Reuse of Collector from the Foam Phase by a Solvometallurgical Process. J. Sustain. Metall. 7, 1565–1574 (2021). https://doi.org/10.1007/s40831-021-00463-y

- Potential of Mechanochemically Activated Sulfidic Mining Waste Rock for Alkali Activation – Niu, H., Adrianto, L.R., Escobar, A.G. et al. Potential of Mechanochemically Activated Sulfidic Mining Waste Rock for Alkali Activation. J. Sustain. Metall. 7, 1575–1588 (2021). https://doi.org/10.1007/s40831-021-00466-9

Symposium "(Re)mining extractive waste, a new business?"

With the ETN SULTAN project entering its final phase, the project organises the Symposium (Re)Mining Extractive Waste, a new Business? on May 17-18, 2022 in Mechelen, Belgium. Co-organisers are EU NEMO and SIM² KU Leuven. Registration and abstract submission are now open. More info below and on https://re-mine.eu/.

The 2-day symposium “(Re)Mining extractive waste, a new business?” gathers leading experts in the field of mining and/or remining of extractive waste. The latest evolutions in the field, novel concepts and business cases will be presented, including case studies from both historical and active mining sites.

The target public comprises industry, academia, policy makers and civil society. Speakers will contribute to four sessions: mapping, resource estimation & geometallurgy; metal and mineral recovery; bulk mineral matrix valorisation; multi-criteria assessment, policy and Social License to Operate (SLO). Oral presentations/poster sessions are combined with workshops on Life-Cycle Assessment (LCA) and SLO aspects of (re)mining extractive waste.

There will be ample networking opportunities. Registration and abstract submission are now open. Invited keynote lectures are combined with oral and poster presentations, which are selected after abstract submission.

- Would you like to participate? Register here https://re-mine.eu/registration/

- Would you like to contribute with an oral or poster presentation? Submit an abstract by February 28, 2022 Latest. Guidelines on abstract submission on https://re-mine.eu/abstract-submission/

- We especially invite speakers presenting successful case-studies of metal/mineral recovery from tailings.

Background on the H2020 MSCA-ETN SULTAN project

For more than 100 years the EU mining industries have been discarding their extractive-waste residues. Estimates suggest this represents 29% of the EU-28’s current waste output. When poorly managed these “tailings” can pose significant environmental hazard. Sulfidic Cu-Zn, Zn-Pb and Cu-Zn-Pb tailings pose the largest challenge, as they are prone to acid mine drainage.

Despite the fact that industry has strongly invested in the development of state-of-the-art “tailings storage facilities” (TSFs) that are equipped with environmental protection technologies – in line with the Mining Waste Directive (2006/21/EC EU) – today the dominant extractive-waste management philosophy is still a conservative one, as its primary concern is to minimise environmental risks through a containment strategy.

However, these tailings can still contain valuable metals. Recently, the European Innovation Partnership (EIP) on Raw Materials launched a “call to arms” to transform the “extractive-waste problem” into a “resource-recovery opportunity”. Additionally, the EIP has warned about the acute shortage of talent in this sector.

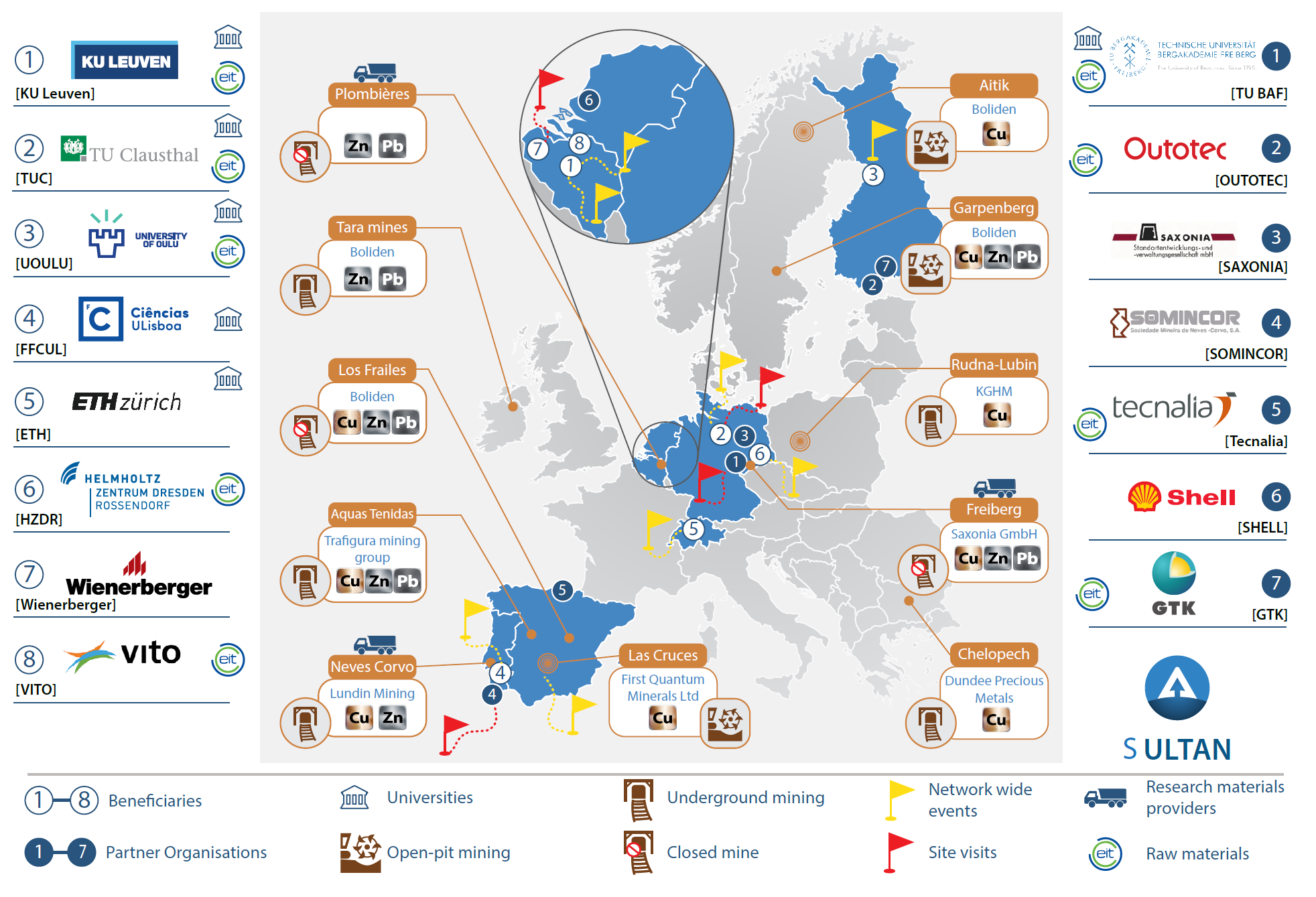

In order to develop a highly skilled workforce, to mitigate environmental risks and to economically recover valuable raw materials, the ITN for the remediation and reprocessing of sulfidic mining waste sites (SULTAN) provides the first-ever training programme dedicated to the reprocessing of tailings. The objective of SULTAN is twofold, i.e. (1) mitigating environmental risks intrinsic to sulphidic tailings (2) recovering both valuable and critical raw materials from Europe’s tailings. A schematic overview of the SULTAN project concept is shown in the image below.

SULTAN develops cutting-edge methodologies to assess the resource potential of Europe’s main sulphidic tailings families (WP1) and explores eco-friendly mining chemicals to be used in advanced metal-extraction/recovery set-ups (WP2). SULTAN not only recovers the metals but also valorises the clean(ed) tailing residues in circular-economy applications, incl. inorganic polymers, green cements and ceramics (WP3). In WP4 a novel environmental assessment methodology is developed. The 15 SULTAN ESRs also benefit from a unique soft-skills training programme (WP5) and maximise the impact of their research through dissemination and exploitation (WP6). More info on the SULTAN project can be found on the SULTAN website: https://etn-sultan.eu/

Acknowledgements

The SULTAN project has received funding from the European Union's EU Framework Programmefor Research and Innovation H2020 under Grant Agreement No 812580.