ProcESS/SIM² KU Leuven researchers precipitated high-quality calcium carbonate (PCC) from synthetic Ca-rich solutions, which resemble the chemical composition of leachates obtained from leaching Basic Oxygen Furnace (BOF) slags with diluted HCl. PCC is used as filler or whitener in a variety of applications such as paper, plastics and paint. They evaluated the addition of different chemicals to improve the yield and quality of the PCC. In particular this study showed the potential of using amine-based organic solvents such as MEA in the synthesis process of carbonate minerals, which opens up the route of combining industrial scrubbing of CO2 from process gases with MEA and carbonate mineral synthesis. The work, which was performed in the framework of the ISPT-funded SUP project, was published in the Journal of CO2 Utilization.

Improving the yield of precipitation

The effect of adding NaOH and different amine-based organic solvents (PEI, MEA and AEEA) was investigated by considering an integrated process: CO2-absorption and mineral carbonation.

Ca conversion was below 15 wt% in the absence of alkaline reagents as alkalinity is reduced when H2CO3 is formed under permanent introduction of CO2. The addition of a substantial amount of NaOH (20 g/L, Ca/Na ratio of 1:1) allowed to significantly increase the Ca-conversion yield to above 80 wt%, and the morphology of calcite particles was modified from scalenohedral-rhombohedral-type to rhombohedral shape by increasing the CO2-gas flow rate from 0.008 to 0.5 L/min.

However, this approach would demand ca. 830 kg of NaOH per tonne of CaCO3, which will result in an excessively high estimated cost of around 330–420 USD per tonne of CaCO3.

Applying amine-based solvents which are used for industrial CO2 scrubbing

Instead of using NaOH, the research team also investigated the use of amine-based solvents. Some of these, mono-ethanol amine (MEA) in particular, are already applied in industrial scrubbing of CO2 from process gases in the chemical industry.

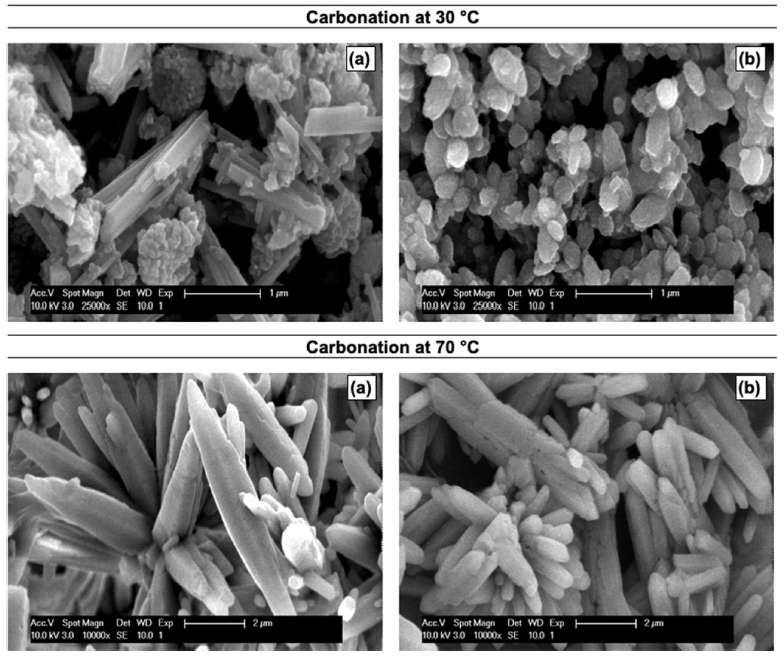

During carbonation with the addition of amine-based organic solvents, MEA and AEEA showed the highest Ca-conversion, i.e. > 80 wt%. A combination of vaterite and aragonite particles was produced at 30 °C, while the formation of pure aragonite prevailed when the temperature was increased up to 70 °C.

The effect of Mg on the formation of aragonite particles was considered negligible due to the low initial concentration, although some traces of Mg were detected in the corresponding final PCC particles. The final PCC resulted with a 99.9 % of purity (Fig. 1) using 5 vol% of solvent, which resulted in a consumption of 2 g of solvent/g PCC.

Real BOF leachates

Later on (not in this publication) the same process was applied to real BOF leachates, with satisfactory results. Further work is devoted to the development of a complete process scheme.

Figure 1. SEM images of PCC formed after carbonation, at 30 and 70 °C, with the addition of (a) MEA and (b) AEEA, and QCO2=0.02 L/min.

Full reference paper

Rodolfo M. Rivera, Tom Van Gerven (2020). Production of calcium carbonate with different morphology by simultaneous CO2 capture and mineralization. Journal of CO2 Utilization, 41, 101241. DOI: 10.1016/j.jcou.2020.101241

Acknowledgements

The project received funding from the Institute for Sustainable Process Technology (ISPT) in the Netherlands and co-funded by TKI-E&I with the supplementary grant 'TKI-Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy, the Netherlands.

Featured image: Aragonite cluster from Podrecany, central Slovakia. (Photo by Albert Russ)