SIM² KU Leuven researchers have characterised the historic Zn-Pb mine waste from the tailings pond located at Plombières, East Belgium. The work, which was published in Minerals, was performed in the framework of the H2020 MSCA-ETN SULTAN project focussing on the remediation and reprocessing of sulphidic mining waste sites.

Why characterise historic mine waste and why is it important for Europe?

Mine waste can be a potential opportunity for secondary deposits for raw materials but also can represent an environmental problem. Contrary to modern mine waste material, the mine waste material from historic deposits is richer in both valuable (e.g. Pb, Zn, Cu) and toxic (As, Cd, S) elements.

Taking into account the economic and environmental aspects, it is of great importance to investigate historic mine waste sites, particularly in Europe, where there is a long legacy of mining, to contribute to a more sustainable circular economy.

This study focuses on the characterisation of different mine waste materials found within the Plombières tailing pond. This historic mining site was selected for the study because the waste material originates from the processing of sulphidic ores. This could present on the one hand an economic opportunity but on the other hand an environmental risk.

Different material within the Plombières tailing pond

The tailing pond occupies a minimum surface of approximately 8,000 m2. During sampling, 4 different main types of materials were noticed within the tailings pond. The mine waste materials sampled at the Plombières site were subdivided into four mine waste types: soil formed on metallurgical waste, metallurgical waste, brown tailings and yellow tailings.

By combining the results from the drilling and geophysical assessment, it was concluded that yellow tailings were the most abundant material, followed by metallurgical waste, brown tailings and soil being least present. During the characterisation of the material, it was noticed that the soil and metallurgical waste show a strong heterogeneity, while the tailings are more homogeneous, but still, there is some variation in the results.

What are the results telling us?

It would be most economically viable to extract Pb and Zn from both the metallurgical waste and brown tailings based on their metal contents. However, the tickness of both units is too thin for economic exploitation. Pb and Zn are located within Pb- and Zn-bearing minerals and slags.

Yellow tailings showed to be the most suitable for application in the ceramic industry due to their low content of metals and metalloids. Although there is a potential for exploitation, it is hampered by the fact that the Plombières area is classified as a nature reserve. The Plombières tailings pond represents a relatively low environmental threat, this is based on the liberation of the acid-generating (e.g. pyrite) and acid-buffer minerals (calcite).

What's next to come?

A better understanding of Pb and Zn deportment is necessary for improved assessments of the recoverability of Pb and Zn in the Plombières mine wastes. Therefore, additional methods will be used for characterisation in the future, including mineral liberation analysis (MLA) and electron microprobe analysis (EPMA).

Based on the overall assessment, further research will focus on the potential extraction methods (e.g., hydrometallurgy) as well as a more advanced characterisation of the materials and more detailed mineral resource estimation.

Full reference of paper

Srecko Bevandic, Rosie Blannin, Jacqueline Vander Auwera, Nicolas Delmelle, David Caterina, Frederic Nguyen and Philippe Muchez, Geochemical and Mineralogical Characterisation of Historic Zn–Pb Mine Waste, Plombières, East Belgium. Minerals 2021, 11, 28. https://doi.org/10.3390/min11010028

Acknowledgements

This project has received funding from the European Union's EU Framework Program for Research and Innovation H2020 under Grant Agreement No 812580.

Credits featured image: Map of the Plombières area showing the location of the tailings pond (Google Maps, 2019, maps.google.com.). Red polygon represents the studied area of the tailings pond. (Creative Commons Attribution 4.0 International)

More info about the SULTAN project

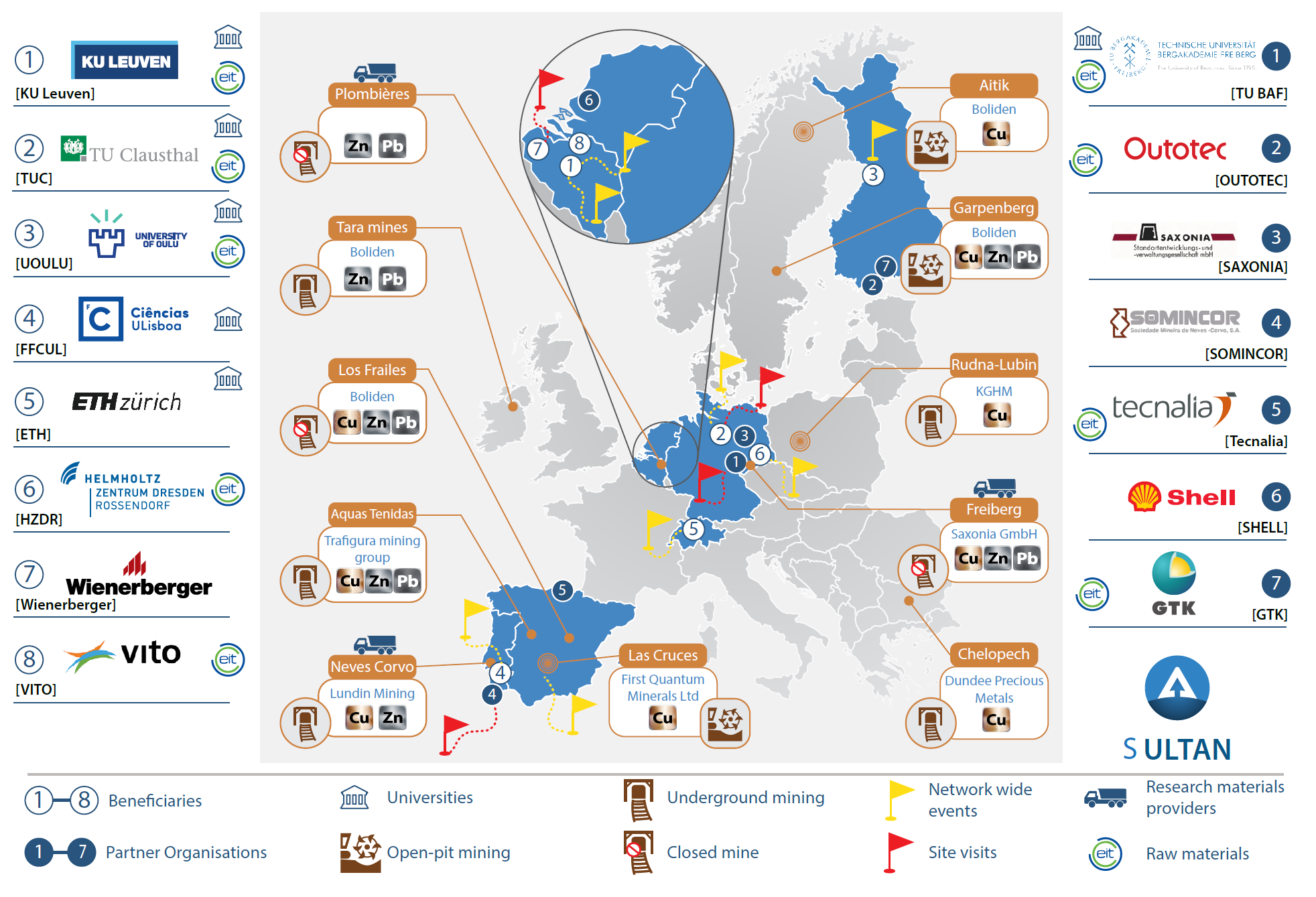

The European Innovation Partnership (EIP) on Raw Materials launched a “call to arms” to transform the “extractive-waste problem” into a “resource-recovery opportunity”. Additionally, the EIP has warned about the acute shortage of talent in this sector. In order to develop a highly skilled workforce, to mitigate environmental risks and to economically recover valuable raw materials, the ETN for the remediation and reprocessing of sulphidic mining waste sites (SULTAN) provides the first-ever training programme dedicated to the reprocessing of tailings. SULTAN has pooled the interdisciplinary and intersectoral expertise of leading EIT RawMaterials members, world-leading mining and chemical companies, covering all the links in the tailings-reprocessing value chain.

SULTAN develops cutting-edge methodologies to assess the resource potential of Europe’s main tailings families (WP1) and explores eco-friendly mining chemicals to be used in advanced metal-extraction/recovery set-ups (WP2). SULTAN not only recovers the metals but also valorises the clean(ed) tailing residues in circular-economy applications, incl. inorganic polymers, green cements and ceramics (WP3). In WP4 a novel environmental assessment methodology is developed. The 15 SULTAN ESRs also benefit from a unique soft-skills training programme (WP5) and maximise the impact of their research through dissemination and exploitation (WP6). This will kick-start their careers as highly employable professionals in the EU’s tailings reprocessing/remediation sector, as well as for geological surveys, teaching and scientific organisations, and public bodies.

Website: https://etn-sultan.eu/